Petrogenium. USA LLC

Headquartered in Houston, Texas, Petrogenium USA LLC represents the next phase of growth for Petrogenium. With president Paul Newman at the helm, our North America-based consultants are ready to tackle projects worldwide.

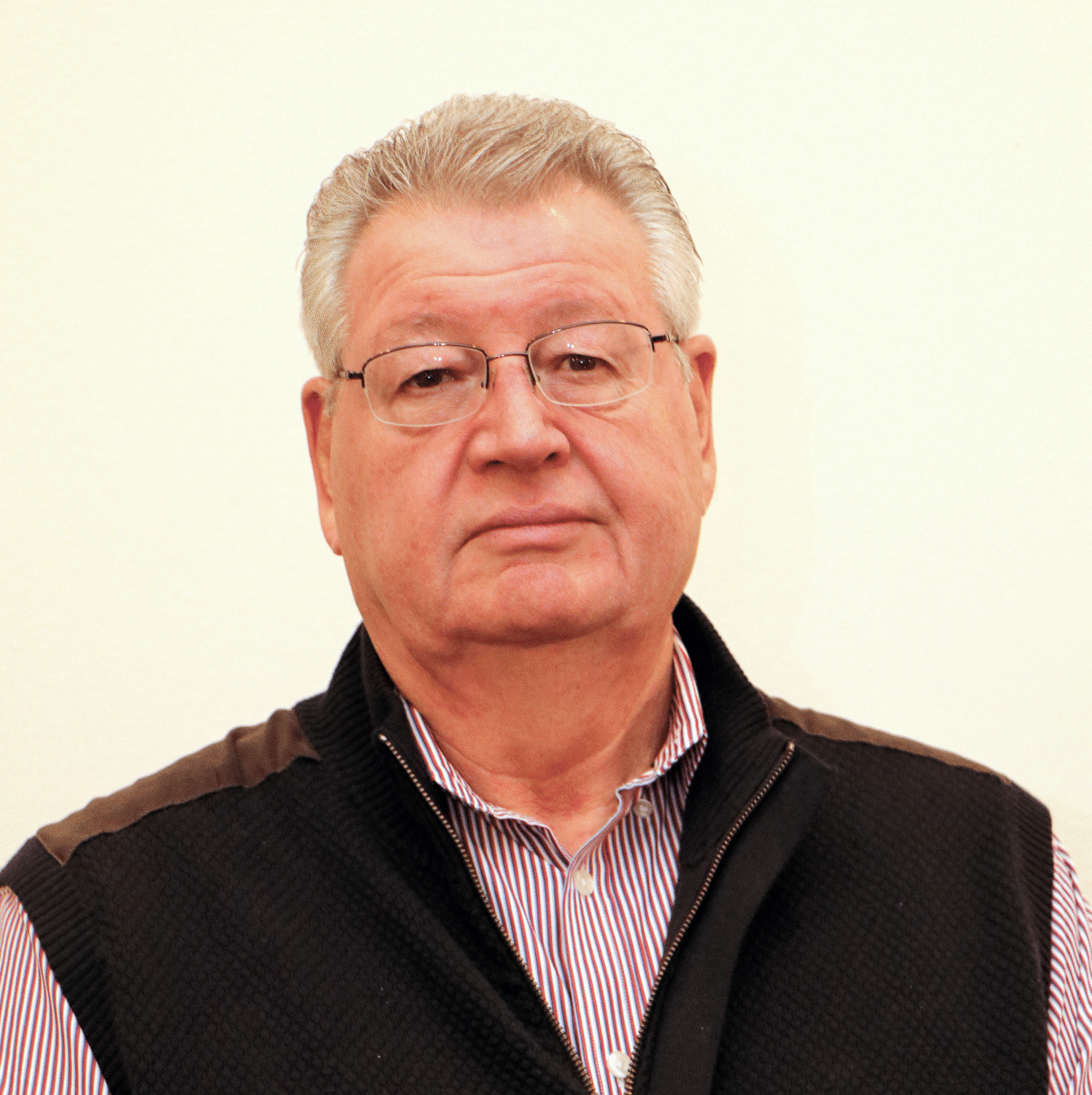

Paul Newman

President Petrogenium USA LLC

For more details please contact:

paul.newman@petrogenium.com

+1-713-715-9920

Paul has cross-functional capabilities and experience which will add value across a wide range of your customers’ businesses. He has a passion for Operational Excellence, HSE, and coaching and mentoring emerging talent. He has a hands-on approach to building trust and helping others grow and develop.

Paul has had a 40-year global career in refining and petrochemicals operational excellence, consultancy, commercial, and complex sales. He spent 35 of those years in Shell Downstream manufacturing leadership. Having served in an operational capacity for two decades as a refining/petrochemicals site manager, he can speak the language up and down the value chain.

After key positions in technical and operations management on large sites in Europe, Paul moved to a more of a strategic role in the leadership of Shell Global Solutions, Shell’s external consultancy.

More recently, he has worked as an external consultant for Bain & Co, Reliance Manufacturing Industries, and Head of Global Consulting Sales and Transformation for Yokogawa/KBC driving digital transformation for global clients.