Sulphur Recovery & Tail Gas Treating Training Course

Consultant/Trainer: Egbert van Hoorn & Frank Oehlschlaeger

The Petrogenium Sulphur Recovery and Tail-Gas Treating training provides unique insight into the design and operation of Sulphur Recovery and Tail gas treating units. Over many years the Petrogenium. experts have gathered deep technical expertise in design, commissioning, start-up, operation, optimization and troubleshooting of SRUs, Tail-Gas Treating units and associated equipment. This knowledge and resulting best practices built the foundation for the course.

Participants

This Petrogenium course can be tailored for awareness/inexperienced staff, for intermediate and for experienced personnel. Furthermore the course can be customized for a specific refinery, plant or unit. The option for post-course consultancy/help-desk support is also available.

Participants may include: engineers as well as operational staff; depending on the participants, the training can receive a theoretical profile or focus more on practical aspects.

The duration of the course is flexible. 1.5 days is the minimum although this can be extended to 3 days dependent on the client: the programme example given is for 3 days. Operator training will typically be limited to 2 days.

Participants may include: engineers as well as operational staff; depending on the participants, the training can receive a theoretical profile or focus more on practical aspects.

The duration of the course is flexible. 1.5 days is the minimum although this can be extended to 3 days dependent on the client: the programme example given is for 3 days. Operator training will typically be limited to 2 days.

Learning Objectives

In the more technology and design focused 3-day course, a wide overview of commercially available and proven technology is provided highlighting pros and cons of each option including their specific limitations. Especially engineers and project developers will find this concept useful. For operators a training program of 2-days, focusing on the actual technology at site, best practices and other operational aspects is available. The operator training is to focus on the process technology installed at the particular site. For this option DCS screenshots of the particular site are included into the course program to allow more site-specific discussion about operating parameters and unit line-ups.

Programme

Day 1

SRU fundamentals:

Day 2

SRU Operations:

Day 3

Tail Gas Treating and Sulphur processes & storage

For the following processes:

SRU fundamentals:

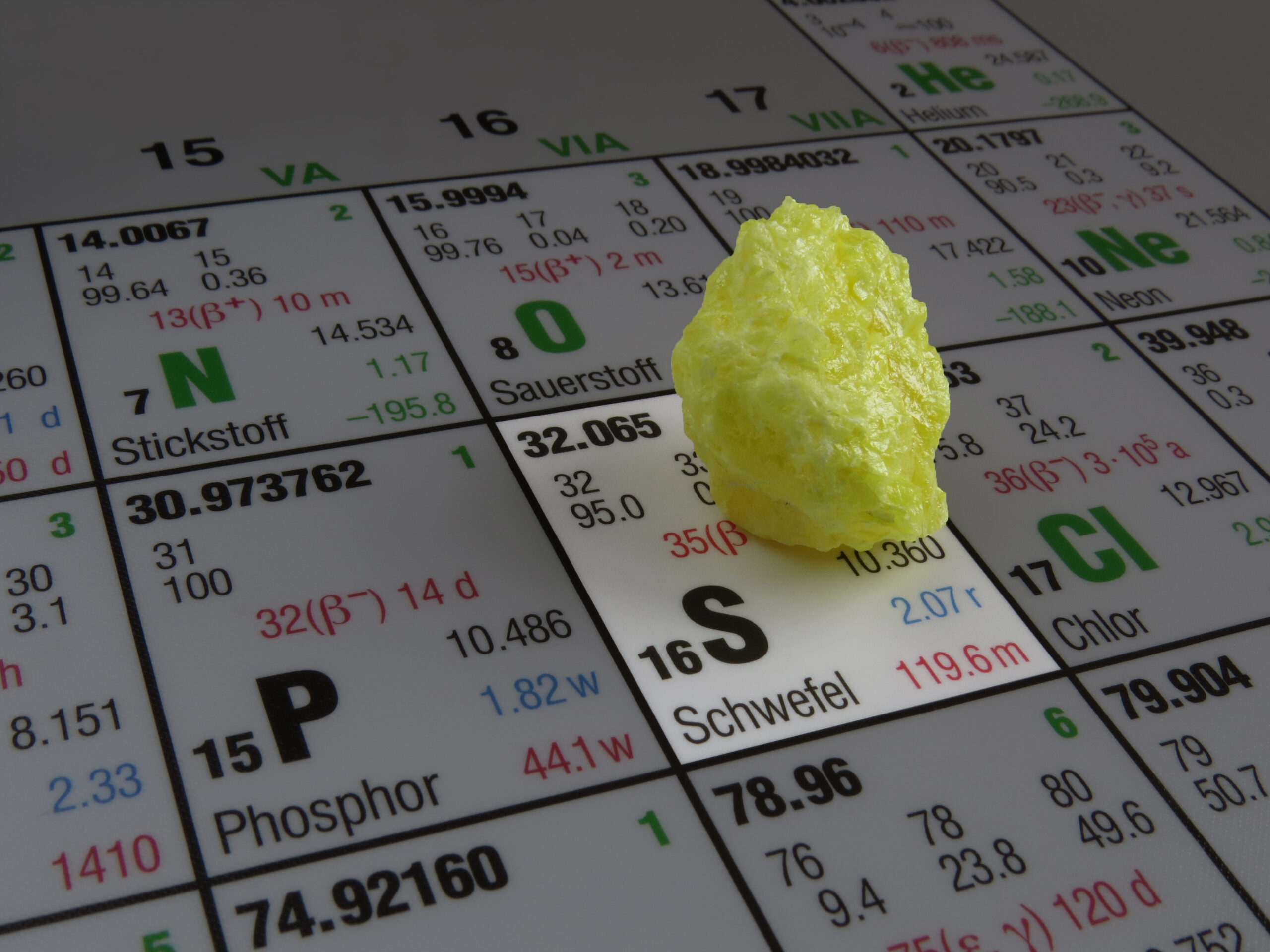

- Introduction and environmental impact

- Sulphur Recovery fundamentals

- Claus reaction

- Modified Claus process

- Side reactions

- Sour water stripper gas processing

- Oxygen enrichment of process air

- Design variations

- Sulphur Recovery Unit equipment

- General design conditions

- Air blower

- Air and acid gas preheater

- Main combustion chamber

- Waste heat boiler

- Sulphur condenser

- Sulphur lock and sulphur piping

- Process gas reheating (direct and indirect)

- Reactor

- Catalyst

- Sulphur coalescer

- Tail gas incineration

- Thermal incineration

- Catalytic incineration

- Sulphur degassing

- Shell sulphur degassing process

- D’GAASS process

- Catalytic enhanced degassing processes

Day 2

SRU Operations:

- Sulphur Recovery Unit instrumentation and control

- SRU commissioning and start-up

- SRU normal operation

- SRU operation monitoring

- SRU shutdown

- SRU hot and cold standby

- SRU trouble shooting

- SRU performance testing and analytical

- SRU process safety

Day 3

Tail Gas Treating and Sulphur processes & storage

For the following processes:

- SCOT process

- Superclaus® and Euroclaus® process

- Sub-dewpoint processes

- Cansolv®

- WSA process®

- Thiopaq®

- Process Basics

- Process Description

- Equipment

- Operational Aspects

- Advantages/Disadvantages

- Alternative Line-Ups

- Sulphur storage