TEMA & HTRI Heat Exchanger Design & Cost Saving Management Training Course

Consultant/Trainer: Bert Boxma

The course provides in-depth practical understanding of major proven heat exchanger technologies and “state of art” fouling mitigation technologies. Pro’s and Con’s of several heat exchanger types are presented with real-life operational examples. This course provides a good mix of theory and common practices using highly interactive case studies where attendees are encouraged to use in-house heat exchanger type selection software and rigorous design/rating world-class software from HTRI.

Now available virtually!

Unlock Your Skills with Our Online Course!

TEMA & HTRI Heat Exchanger Design & Cost Saving Management is now available online. Click below to send an email for more information!

Participants

This Petrogenium course can be tailored for awareness/inexperienced staff, for intermediate and for experienced personnel. Furthermore the course can be customized for a specific refinery, plant or unit. The option for post-course consultancy/help-desk support is also available.

Participants could include a wide range of Technical Professionals but will greatly benefit:

Participants could include a wide range of Technical Professionals but will greatly benefit:

- Engineers in disciplines Process, Mechanical, Project acting as specialist or generalist

- Design Specialist in heat exchanger to extend their knowledge HTRI specific

- Engineers in various disciplines; Maintenance, Turn-Around, & Cost Estimating

Learning Objectives

By the end of this course, participants will be able to perform or become:

- Proper Heat Exchanger Selection

- Heat Exchanger sizing

- Active Communicator during Meetings with Vendors

- Better observer during final inspection of heat exchangers

- Clear understanding of HTRI results

Day 1 – Shell and tubulars

Day 2 – Shell & Tubulars Advanced Technologies

Day 3 – Vibration Analysis and HTRI / TEMA Case Studies

Day 4 – Air Cooled & Compact Heat Exchangers

Day 5 – HTRI Thermal Design Aspects Condensers& Reboilers

- Historical & Market Aspects

- Basic Heat Transfer

- Mean Temperature Difference & Thermal Efficiency

- Fundamentals of Stream Analysis

- TEMA Nomenclature & Selection

- Shell, Bundle, Baffle and Tube type Selection

Day 2 – Shell & Tubulars Advanced Technologies

- Fouling Mitigation Technologies

- High Pressure Breech Lock Closure type

- Texas Tower, Helitower, Helixchanger, Helifin, Helitrans

- Tube Insert Technologies

- Low-fin, High-flux, Corrugated and Twisted Tube applications and examples

Day 3 – Vibration Analysis and HTRI / TEMA Case Studies

- Tube Vibration and FIV Prevention Technologies

- Case Study Selection of TEMA type

- HTRI Case study

Day 4 – Air Cooled & Compact Heat Exchangers

- Air Cooled & Economizer Type

- Double Pipe, Hairpin

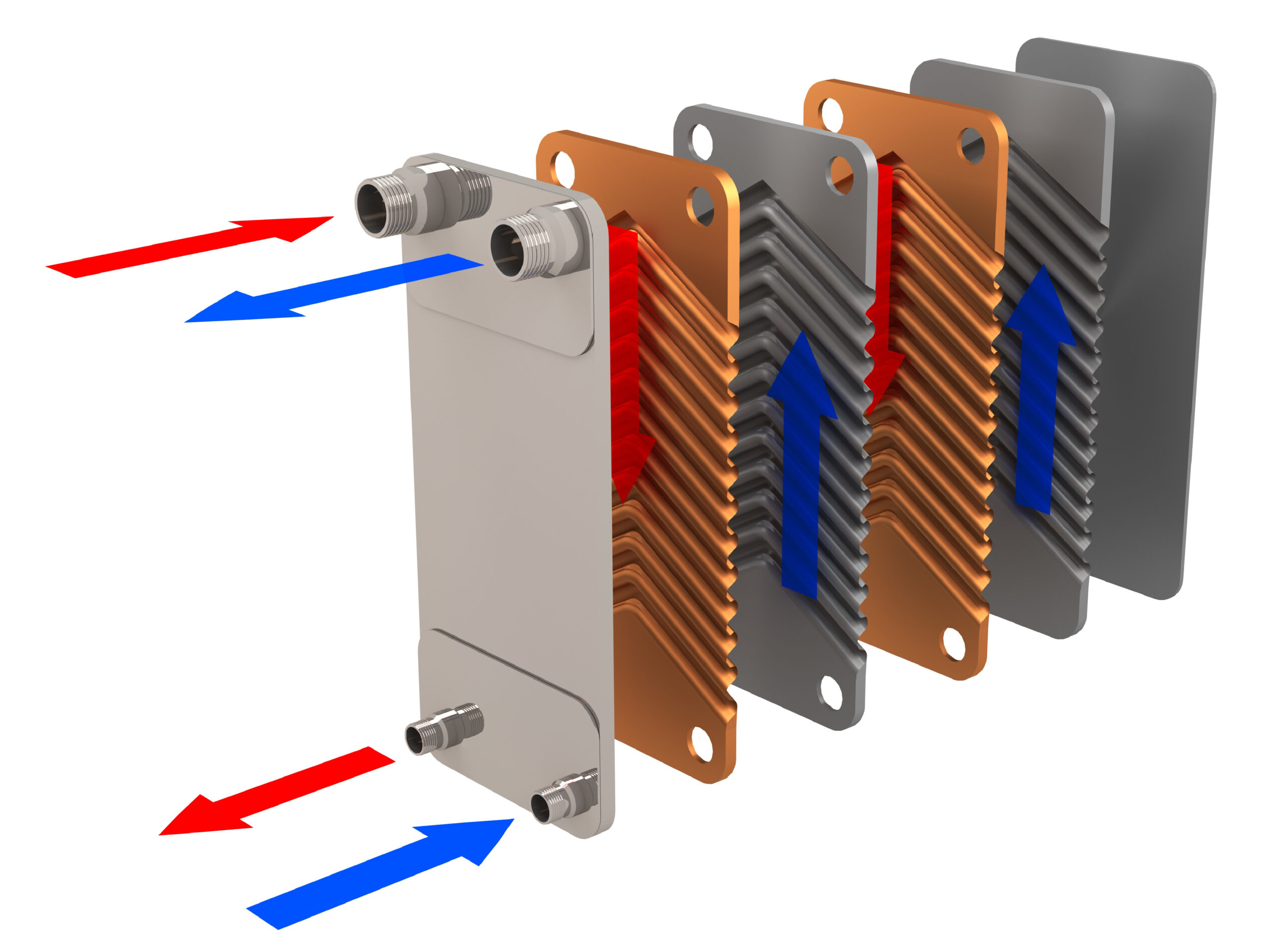

- Plate & Frame, Spiral Plate & Spiral Coil

- Welded Plate (Printed Circuit, Packinox, Brazed Aluminum)

- Submerged & Waterbath Type

- Open Rack Vaporizer

- Case Studies on Selection

Day 5 – HTRI Thermal Design Aspects Condensers& Reboilers

- Practical Aspects of Condenser Design (Reflux, Vent, Shellside versus Tubeside)

- Practical Aspects of Reboiler Design (Thermosyphon, Kettle, Falling Film)

Programme

Day 1 – Shell and tubulars

Day 2 – Shell & Tubulars Advanced Technologies

Day 3 – Vibration Analysis and HTRI / TEMA Case Studies

Day 4 – Air Cooled & Compact Heat Exchangers

Day 5 – HTRI Thermal Design Aspects Condensers& Reboilers

- Historical & Market Aspects

- Basic Heat Transfer

- Mean Temperature Difference & Thermal Efficiency

- Fundamentals of Stream Analysis

- TEMA Nomenclature & Selection

- Shell, Bundle, Baffle and Tube type Selection

Day 2 – Shell & Tubulars Advanced Technologies

- Fouling Mitigation Technologies

- High Pressure Breech Lock Closure type

- Texas Tower, Helitower, Helixchanger, Helifin, Helitrans

- Tube Insert Technologies

- Low-fin, High-flux, Corrugated and Twisted Tube applications and examples

Day 3 – Vibration Analysis and HTRI / TEMA Case Studies

- Tube Vibration and FIV Prevention Technologies

- Case Study Selection of TEMA type

- HTRI Case study

Day 4 – Air Cooled & Compact Heat Exchangers

- Air Cooled & Economizer Type

- Double Pipe, Hairpin

- Plate & Frame, Spiral Plate & Spiral Coil

- Welded Plate (Printed Circuit, Packinox, Brazed Aluminum)

- Submerged & Waterbath Type

- Open Rack Vaporizer

- Case Studies on Selection

Day 5 – HTRI Thermal Design Aspects Condensers& Reboilers

- Practical Aspects of Condenser Design (Reflux, Vent, Shellside versus Tubeside)

- Practical Aspects of Reboiler Design (Thermosyphon, Kettle, Falling Film)